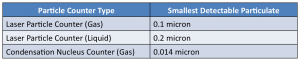

Particle Analysis

Independent QA/QC offers a wide range of particulate analysis services including material/component qualification, gas/chemical/liquid distribution system qualification and monitoring, process tool trouble shooting as well as cleanroom certification to ISO 14644. Independent QA/QC utilizes particle counters manufactured by Particle Measurement Systems (PMS), Lighthouse Worldwide and Met One for analysis of process gas systems and clean room certification/monitoring. Particle analysis is performed by means of a condensation nucleus (CNC) or laser particle (LPC) counters down to the following particulate sizes:

Click on image to increase size

All particle counters are calibrated to manufactures recommendations to traceable NIST calibration standards.

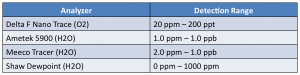

Trace Gas Analysis

Independent QA/QC offers trace gas (O2/H2O) analysis for a variety of stainless steel process gas and chemical distribution systems. Services range from installation certifications prior to commissioning, on line process gas monitoring as well as process tool trouble shooting. Elevated levels of trace gas contaminants can be an indication of substandard materials and installation practices, source gas contamination, atmospheric leaks or purifier breakthrough. Independent QA/QC utilizes oxygen analyzers manufactured by Delta F and moisture analyzers manufactured by Ametek, Meeco and Shaw. Detection ranges for trace gas analyzers are as follows:

Click on image to increase size

All trace gas analyzers are calibrated to manufactures recommendations to traceable NIST calibration standards.

Independent QA/QC can also perform cost effective hydrocarbon (THC) and atmospheric molecular contamination (AMC) sample collection services utilizing sample bombs, DI impingers and Tenax tubes with analysis performed by third party laboratories.

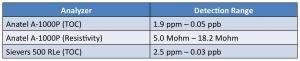

TOC/Resistivity Analysis

Independent QA/QC offers comprehensive total organic carbon (TOC) and resistivity analysis for ultra pure water systems. Analysis can be performed prior to system commissioning, in-situ system monitoring as well as for process tool trouble shooting. TOC contamination levels in UPW are becoming increasingly critical for the semiconductor industry as circuit dimensions continually shrink as well as with the increasing adoption of immersion lithography. Independent QA/QC utilizes analysis equipment manufactured by Anatel. Detection ranges for UPW analyzers are as follows:

Click on image to increase size

All UPW analyzers are calibrated to manufactures recommendations to traceable NIST calibration standards.